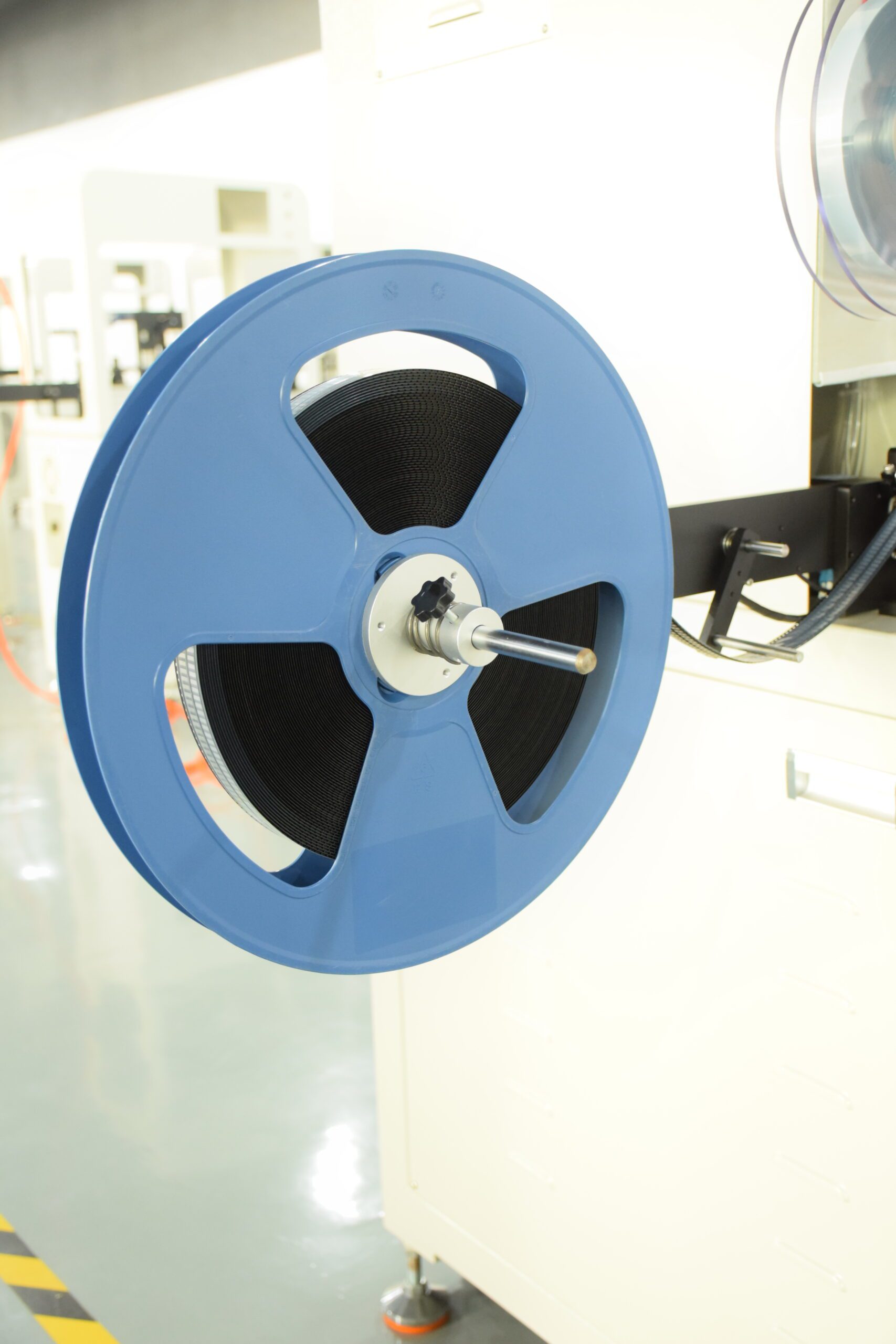

Automatic Tape and Reel Equipment Supplier

Trusted by our customers, we deliver expertise and help cut packaging costs.

High Capacity and Quality

Custom Solutions

24/7 Online Support

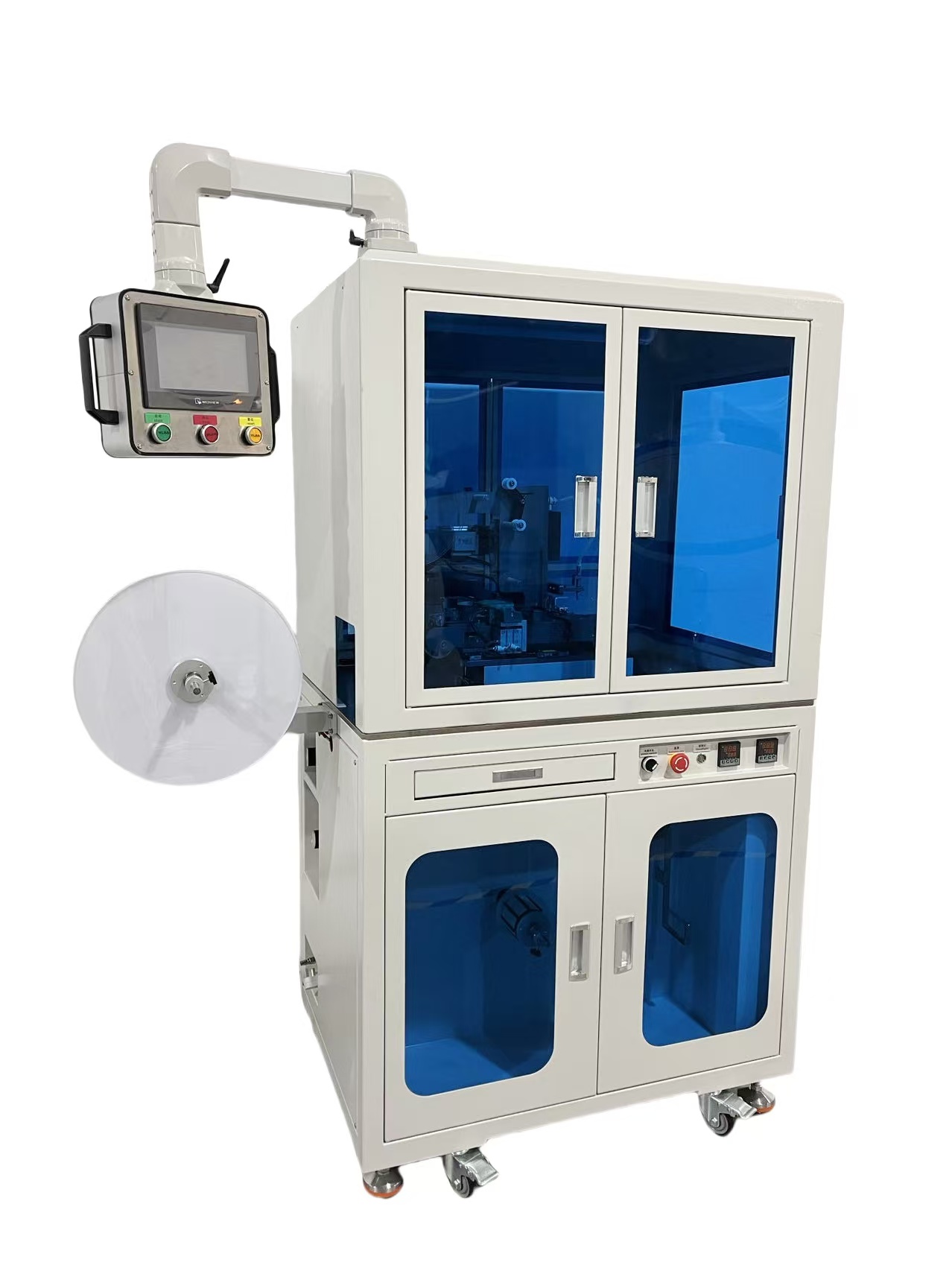

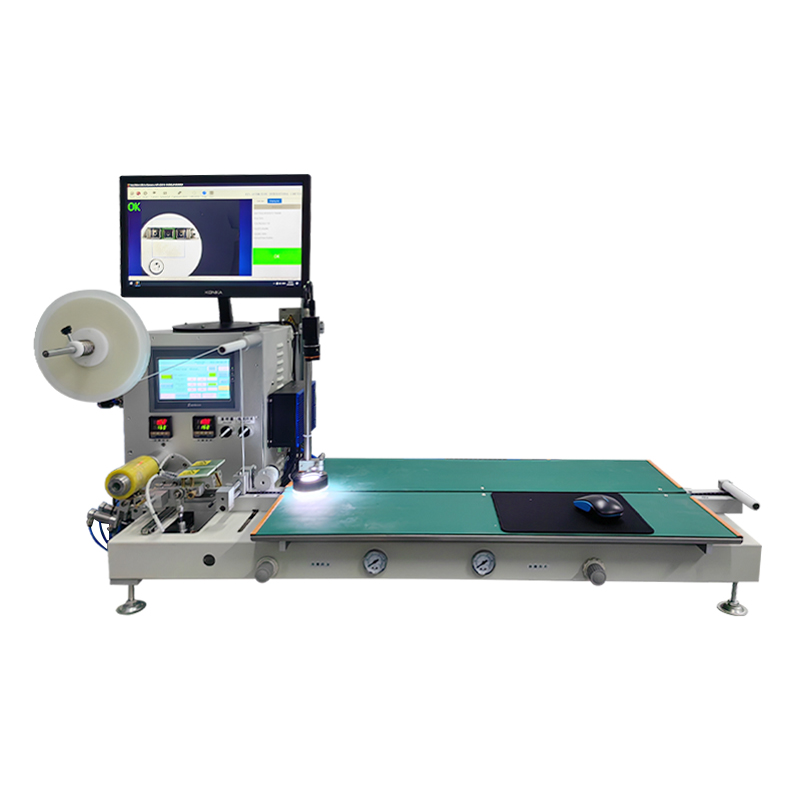

KST-RA10

Vibration-bowl Taping Machine

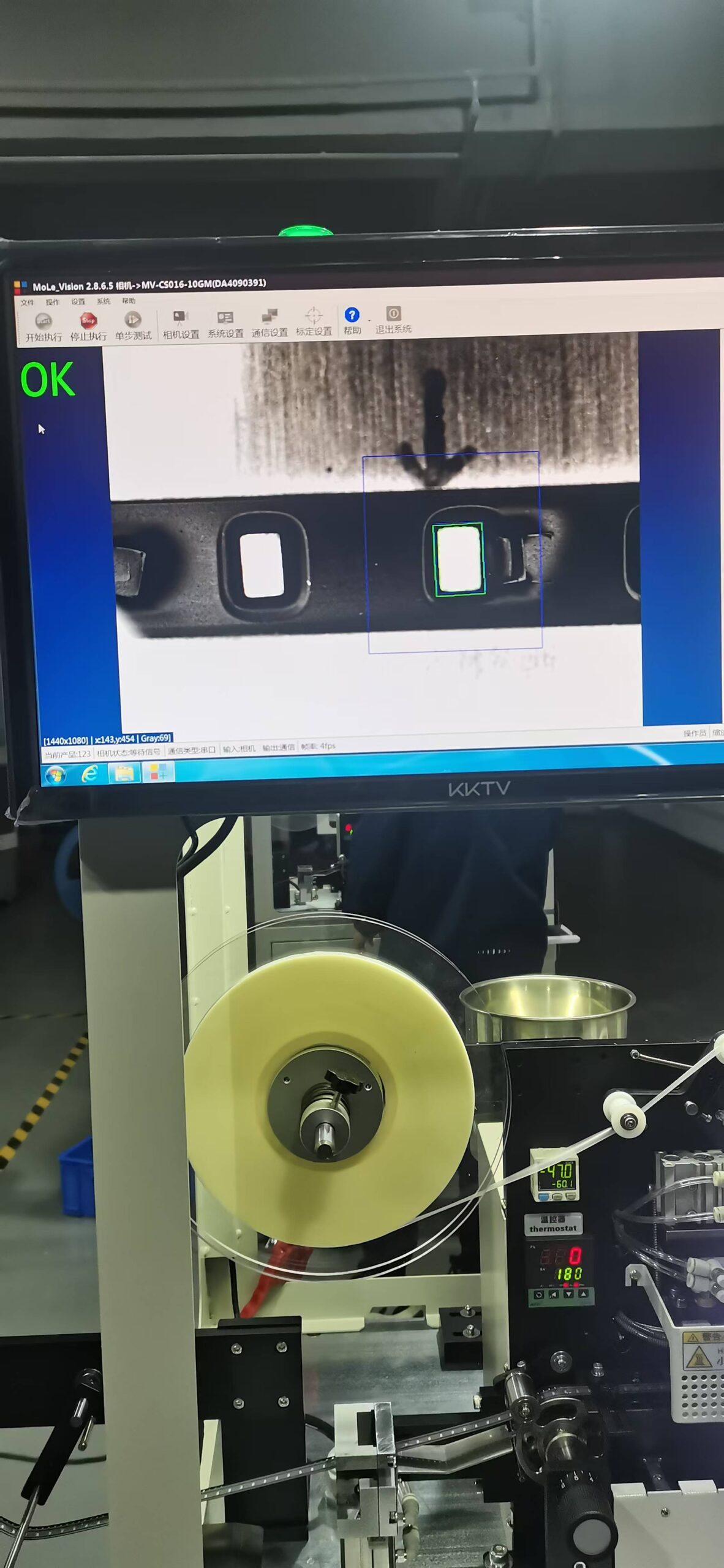

The KST-RA10 uses a swing-arm design and feeds parts through a vibratory bowl, with an automatic hopper to add more parts. The vibratory bowl adjusts the parts into the correct position, then moves them to a linear vibrating track. A robotic arm picks and places the parts, and the tape-and-reel system automatically completes the process. Extra vision inspection can be added based on product needs, such as appearance, size, shape, characters, defects, and surface flatness, etc.

Product Specifications

Feeder: vibration bowl

Capacity: UPH 7-15K(limited by input device and processes required)

Control method: PLC + Touchscreen + Servo motor

Working environment: -5℃-50℃(No corrosive gas, harmful gas, flying dust, etc.)

Dimensions:L1500mm*W700mm*H1450mm、weight 200㎏

Power supply: single phase AC220V/50HZ

Air supply: 0.4-0.9Mpa

Features and Benefits

Adjustable carrier tape output from 8mm-72mm width

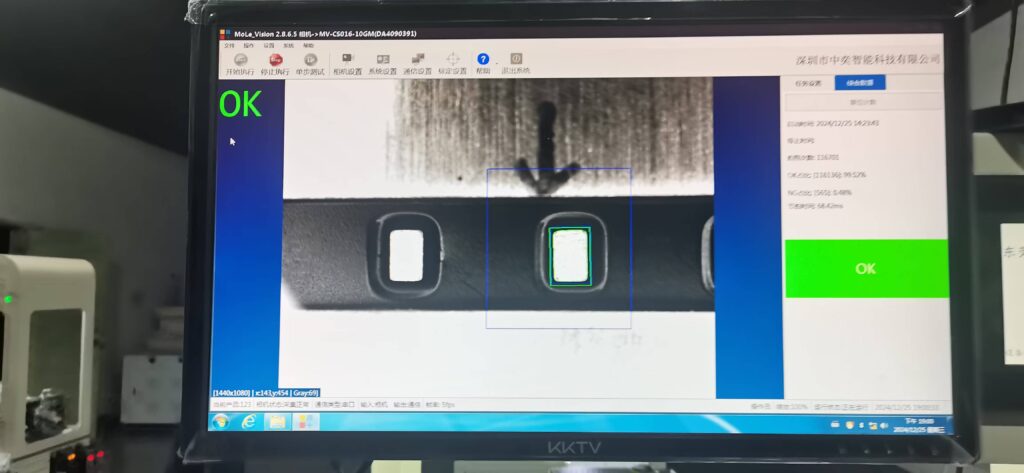

Vision inspection display and result reporting

Function Test:Yes

Defect Detection: Yes

Reject sorting

Self-adhesive/ Heat- sealing

Touchscreen Interface

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

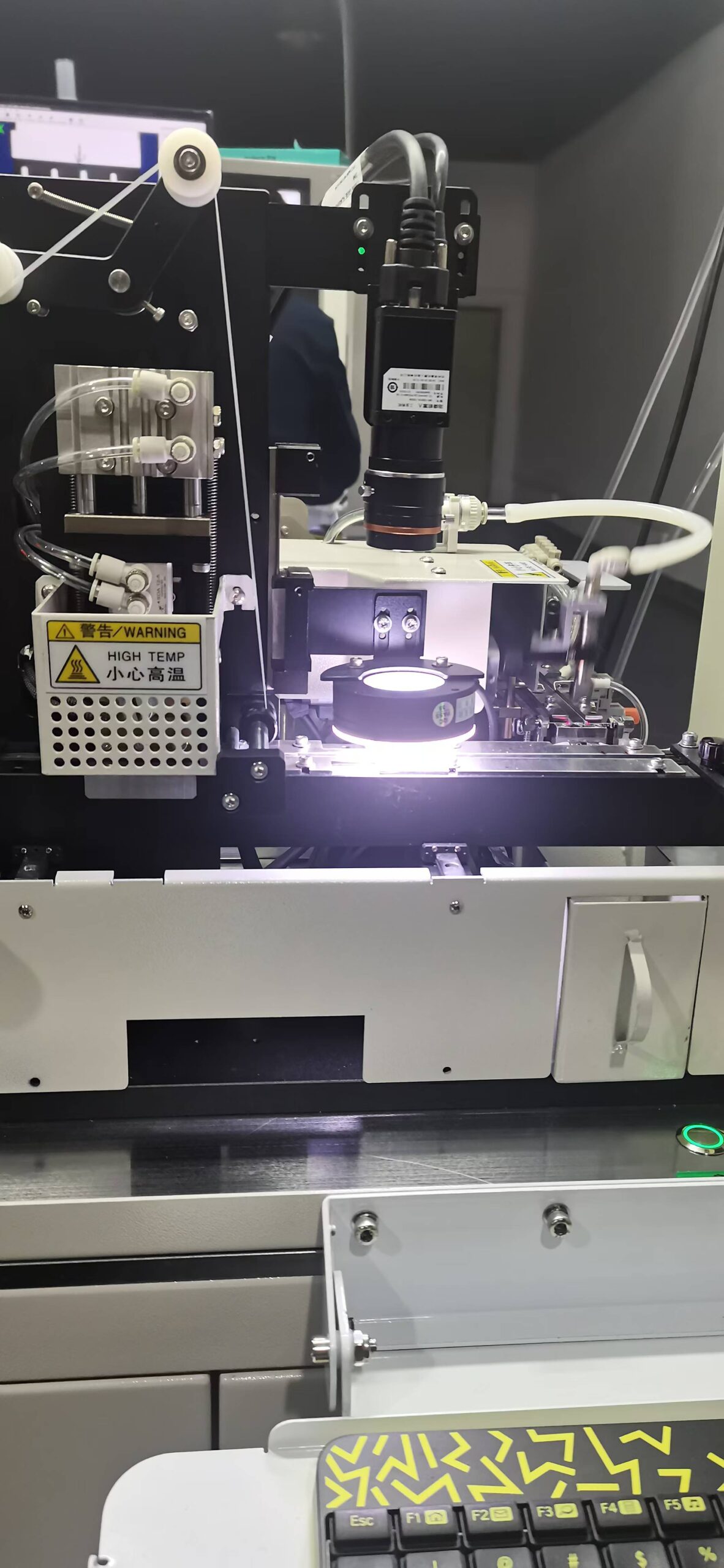

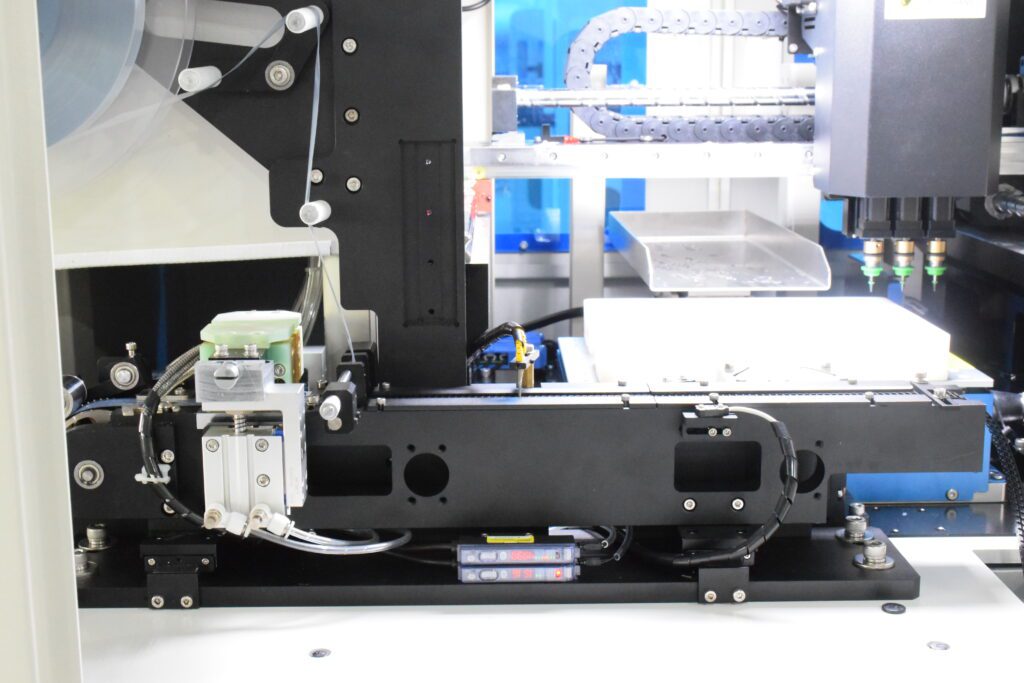

KST-FB20

Multifunctional Flexible Tape and Reel Machine

The KST-FB20 features a flexible feeding system with pick-and-place, testing, inspection, and tape-reeling functions, making it perfect for low-volume, mixed production environments. The multiple input options minimize the need for extra machines, The output can be in either reels or trays, depending on the customer’s needs. The touchscreen interface simplifies setup and reduces operator intervention, ensuring efficient operation.

Product Specifications

Feeder: Flexible bowl

Capacity: UPH 3-4K ( device dependent)

Control method: PLC + Touchscreen + Servo Motor

Working environment: -5℃-50℃

Dimensions: L2204mm* W960mm*H1957mm

Power required: Single phase AC220V/50HZ

Air supply: 0.4-0.9Mpa

Features and Benefits

Flexible bulk input and automated handler with different components

Optional tape output in trays or tapes

User-Friendly Touchscreen interface

Vision inspection available

Reject sorting

Self-adhesive or heat- sealing

Reject sorting

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

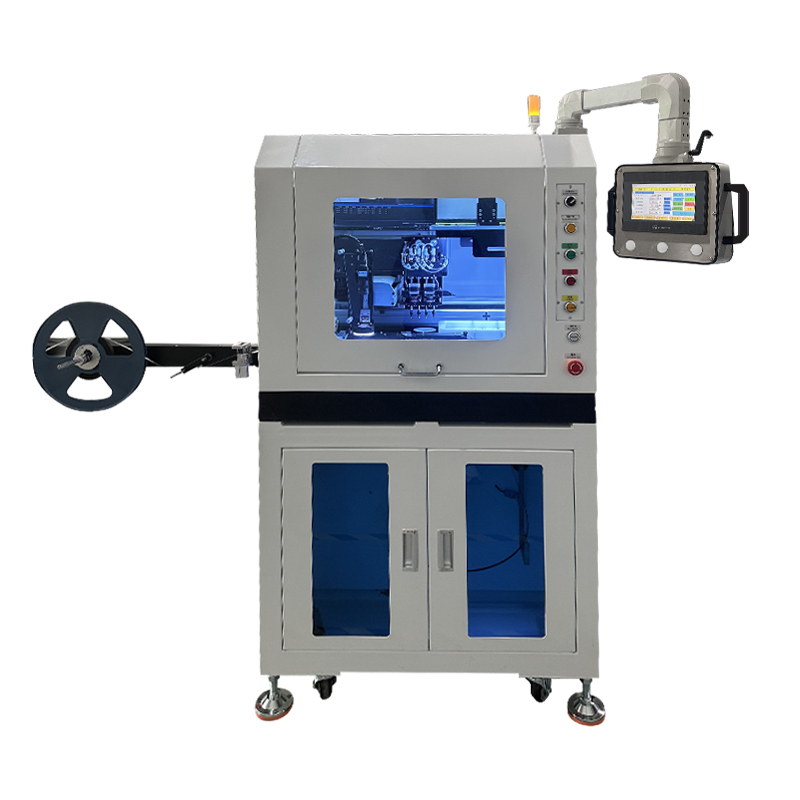

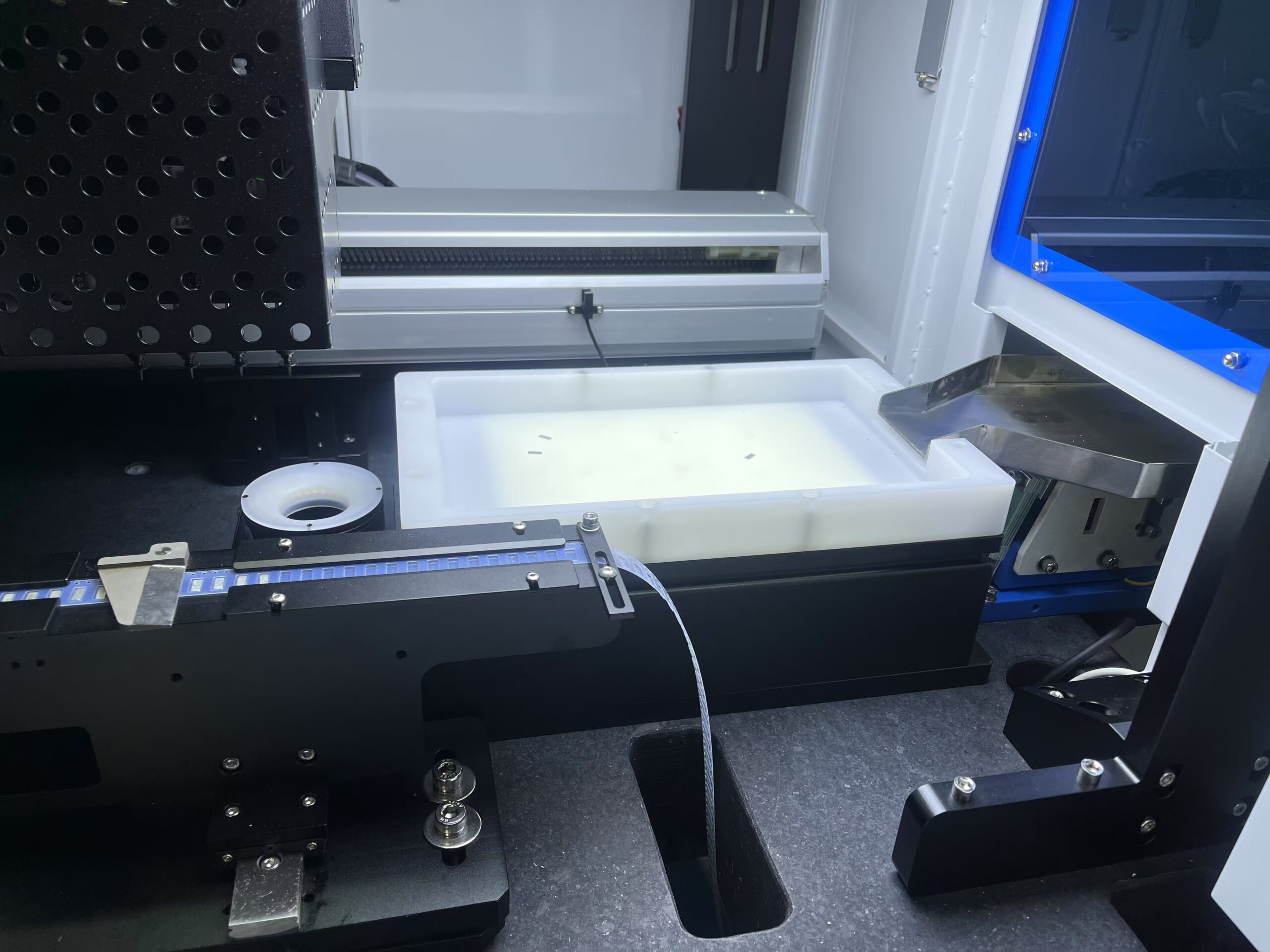

KST-TRL60

Automated Tray to Tape Machine

The KST-TRL60 automatically changes components from tray packaging to reel packaging. Components are fed from the tray, and PLC calculates the spacing. A robotic arm picks up the components. After checking with a CCD camera, bad items (NG) are removed, and good items (OK) are placed into the carrier tape and sealed. It’s good for ICs, modules, hardware parts, and other tray-fed items. A CCD visual inspection module can be added if needed.

Product Specifications

Feeder: Tray Feeding/JEDEC Tray/ Custom Tray

Capacity: UPH 8-15K (Device dependent)

Tape output adjustable between Width≦72mm, Depth≦10mm

Dimensions: L2204* W960*H1957mm

Testing Function: Per customers’ request

Working environment: -5℃-50℃(No corrosive gas, harmful gas, flying dust)

Power Supply: Single phase AC220V/50HZ

Features and Benefits

Adjustable carrier tape output from 8mm-72mm width

Vision inspection display and result reporting

Function Test:Yes

Defect Detection: Yes

Reject sorting

Self-adhesive/ Heat- sealing

Touchscreen Interface

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

KST-UT80

Automated Tube to Tape Machine

The KST-UT80 is an automatic system that delivers high performance at a reasonable cost. It can process tube-fed components at a speed of up to 8000 units per hour. The TM-600 is perfect for low to mid-volume production, offering a fast, efficient, and affordable way to get components into tape and reel.

Product Specifications

Feeder: Tube Feeding

Capacity: UPH 8-15K (device dependent)

Control Method: PLC + Touchscreen + Servo motor

Dimensions: L1040mm*W1020mm*H1400mm, Weight180㎏

Power supply: Single phase AC220V/50HZ

Air Supply: 0.5-0.9Mpa

Features and Benefits

Tube in, tape out; / tube in, tray out; /tube in, tube out;

Automatic detection of empty tubes.

Vision inspection.

Marking funciton

Self-adhesive or heat- sealing

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

KST-TTR30

Automated Tube to Tray Machine

This KST-TTR30 can convert components from tube to tray packaging, and is suitable for items like SOP, PLCC, QFN, FPC, and other tube-fed items.

Product Specifications

Feeding System: Tube Feeding

Capacity: UPH 8-15K

Control method: PLC + touchscreen + servo motor

Working environment: -5℃-50℃(No corrosive gas, harmful gas, flying dust)

Dimensions: L1400mm*W 1500mm*H 1590mm

Power supply: Single phase AC220V/50HZ

Air supply: 0.5-0.8Mpa

Features and Benefits

Automatic tube feeding system with gravity discharge and precise positioning

Automatic detection of empty tubes

Can convert tube to tray packaging

Can check product direction, front/back, defects, and perform performance tests as needed

A laser / inkjet marking module available

Supports both self-adhesive and heat sealing

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

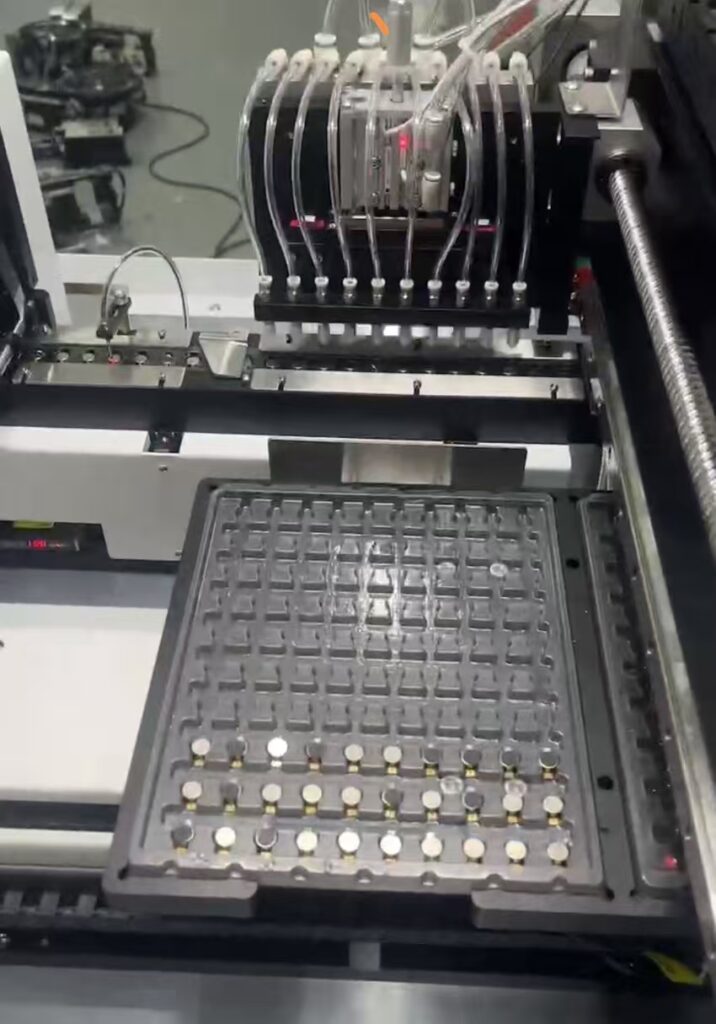

KST-TR19

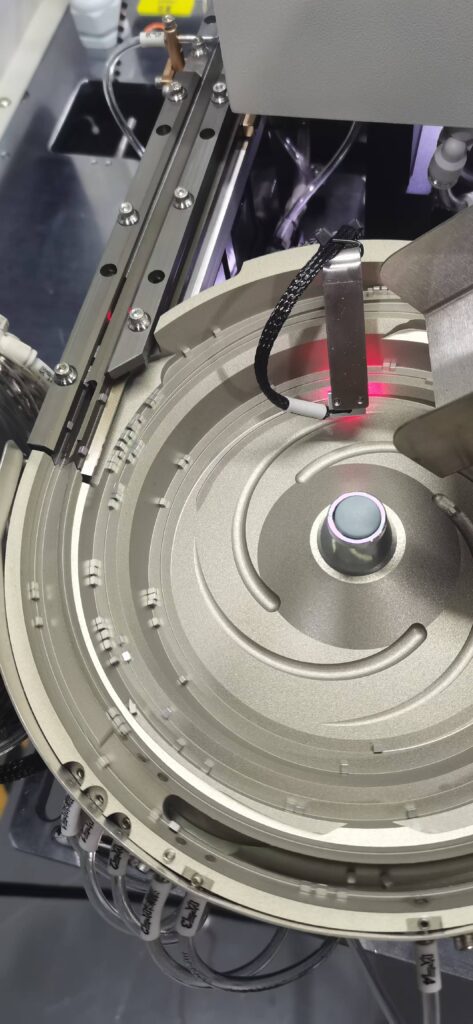

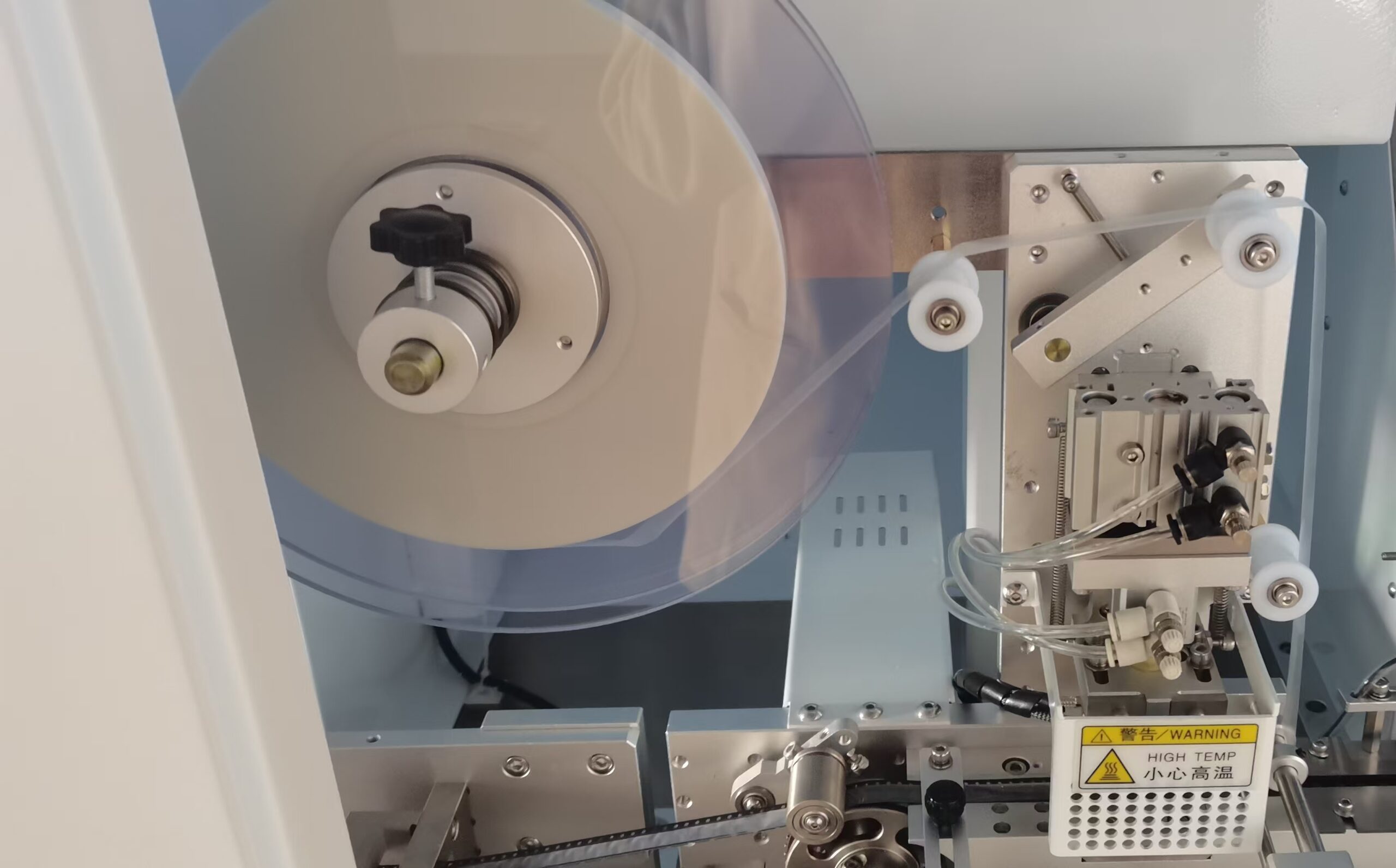

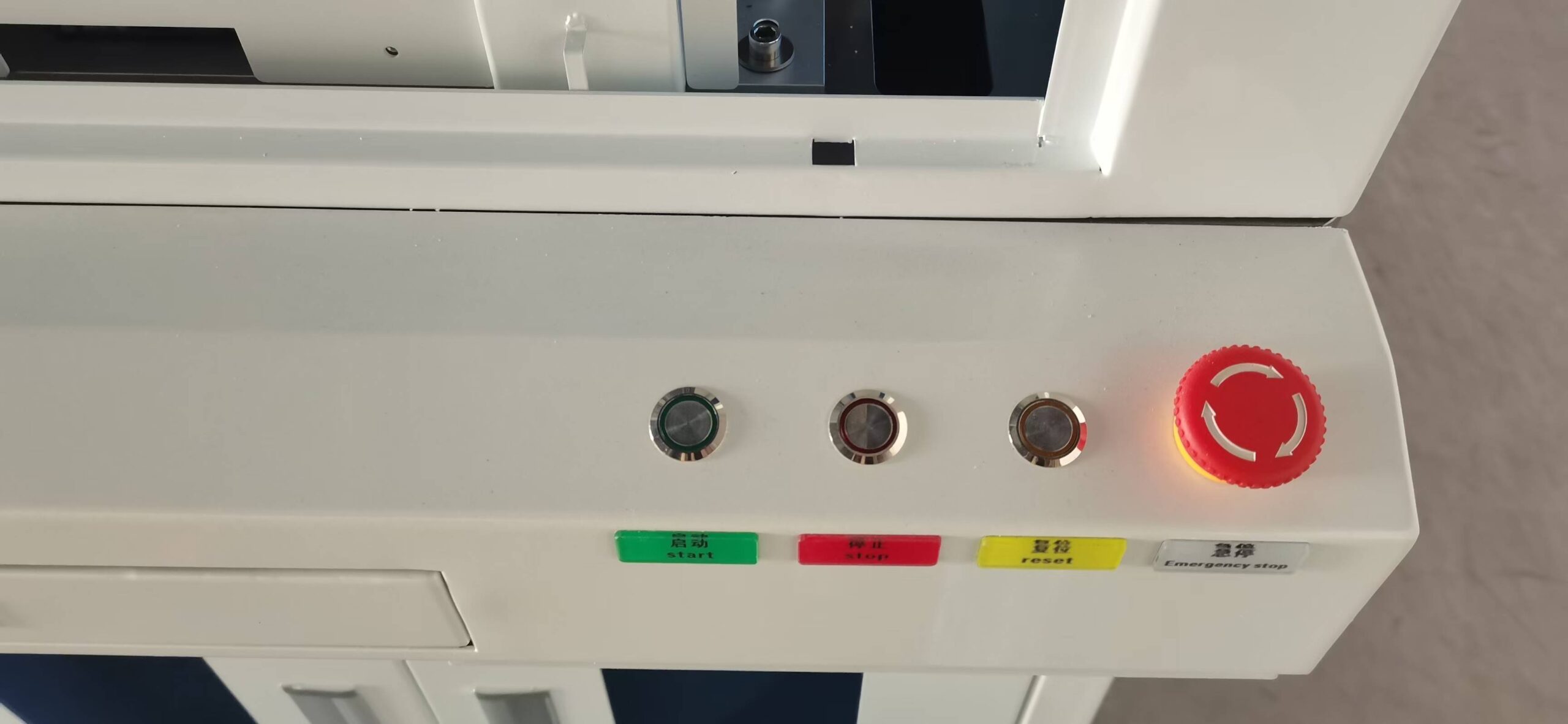

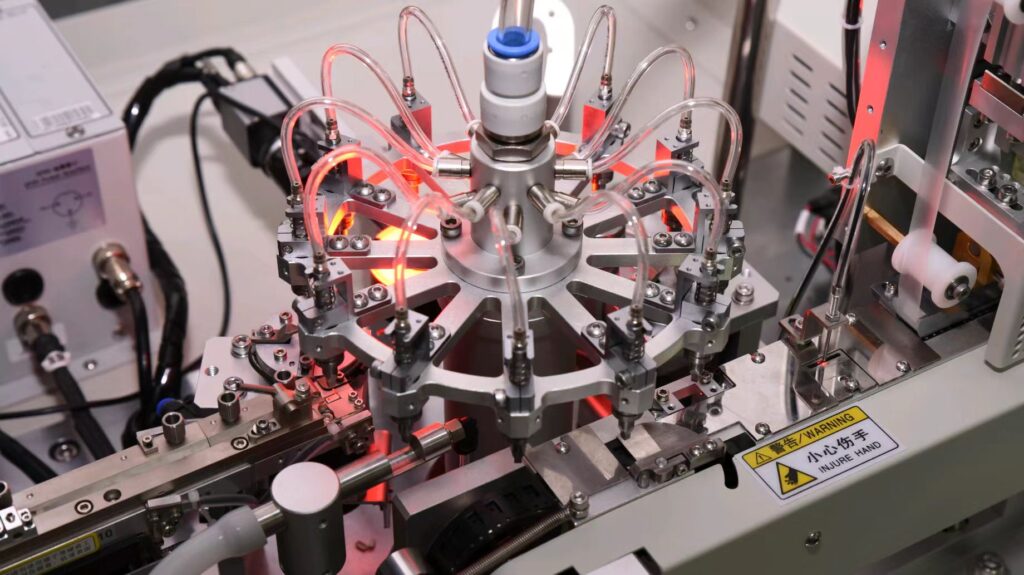

Turret Tape and Reel Machine

The KST-TR19 has a turret design and uses a vibratory bowl to feed materials like electronic components. It also has an automatic hopper to add more materials. The vibratory bowl uses its structure and sensors to adjust the materials’ position, then sends them to a straight vibrating track. The turret picks up materials from this track, and each station can do different tasks like testing, positioning, and removing bad materials. The advantage of turret tape-and-reel machine is fast and efficient.

Product Specifications

Production output: Carrier tape pitch 2-144mm, 8-72mm width

Capacity: UPH 8-25K ( limited by input device and processes required)

Feeder: vibration bowl

Control Method: PLC + Touchscreen + Servo Motor

Working Environment: -5℃-50℃(No corrosive gas, harmful gas, flying dust)

Dimensions: L1500mm * W740mm * H1600mm

Power supply: Single phase AC220V/50HZ

Air supply: 0.4-0.9Mpa

Features and Benefits

User-Friendly Touchscreen interface

Vision inspection: available(CCD, or 5-sided & 3D)

Function test:available(supports multiple sites around the turret)

Defect Detection & Waste Removal: available

Laser marking: available

Self-adhesive or heat- sealing

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

KST-SEMI10

Manual Tape and Reel Machine

This machine uses a PLC control system and a stepper motor to control speed. It has mechanical gears and a counting module to track the number of items per tray and the total production for each shift. A touchscreen can be added for easy use, and it can seal with either cold or heat.

Product Specifications

Feeder: Manual loading

Capacity: Depending on the manual loading speed

Dimensions: L1467mm* W320mm*H485mm, Weight 85㎏

Power supply: Single phase AC220V/50HZ

Air Supply: 0.3-0.6Mpa

Features and Benefits

Touch Screen Interface

Vision inspection can be added

Options and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!