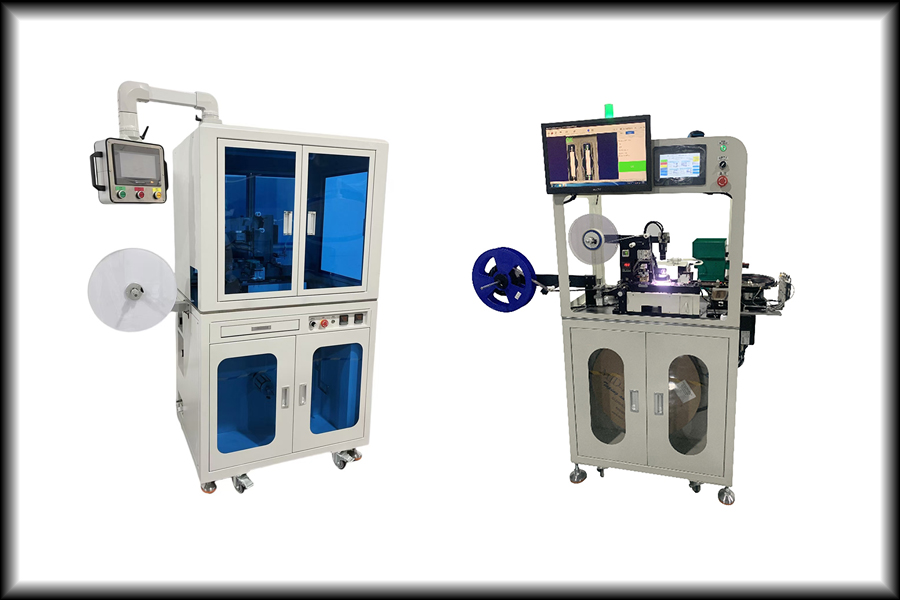

KST-TRL60

Automated Tray-to-tape packaging machine

The KST-TRL60 automatically moves parts from tray packaging to reel packaging. It starts by feeding parts from the tray, and a PLC system calculates the spacing. A robotic arm picks up the parts, checks them with a CCD camera, and removes any defective ones (NG). Good parts (OK) are placed into the carrier tape and sealed. This machine works well for ICs, modules, hardware, and other tray-fed items.

Parameters

Feeder: Tray feeding/JEDEC Tray/ Custom Tray

Capacity: UPH 8-15K (Device dependent)

Tape output adjustable between Width≦72mm, Depth≦10mm

Dimensions:L2204* W960*H1957mm

Testing project: Per customers’ request

Control method: PLC + touchscreen + servo motor

Working environment: -5℃-50℃(No corrosive gas, harmful gas, flying dust, etc.)

Power supply: single phase AßC220V/50HZ

Air supply: 0.4-0.9Mpa

Features& benefits

Change from tray to tape.

Fine control for precise sealing, within sealing line ±0.1mm

Dual independent PID temperature control.

Vision inspecation

Defect inspection

Settings and production counts are saved even after the power is turned off.

Optional Extras

Get in touch with our sales and technical team to customize a machine to suit your needs today!

contact us to customize your machine

Tray-to-Tape & Packaging Solutions

What is Tray to Tape Packaging?

Tray to tape packaging automates the transfer of electronic parts from trays to reels for safe storage and shipping. This method is ideal for sensitive parts like ICs and semiconductors, which require careful handling. As a result, it’s a great choice for large-scale packaging, ensuring speed, accuracy, and minimal errors.

Benefits of Tray to Tape Packaging

Automation: the tray to tape machine reduces manual work, which speeds up the packaging process and improves reliability. This is especially beneficial for large production runs.

Efficiency: the system works quickly, which means you can package more components in less time.

Cost-Effective: By automating the process, the system reduces labor costs and minimizes waste, making tray to tape packaging an affordable option for high-volume production.

Versatility: the system can be customized based on your components, including ICs, semiconductors, and small parts, offering flexibility for various packaging needs.

How Does Tray to Tape Packaging Work?

The tray to tape process includes several important steps:

Tray Loading: Initially, components are placed in a tray to make handling easier.

Visual Inspection: After loading, the components undergo a visual inspection. Based on customer requirements, this inspection can include measuring the size (length, width, and height), checking flatness, and performing electrical tests (such as optocoupler checks or other electrical inspections). Furthermore, the system looks for scratches, marks, and ensures the components are in the correct orientation. Only the components that pass these checks move to the next step.

Component Transfer: Once inspected, the tray to tape system picks up each component from the tray and places it precisely on the tape.

Sealing and Packaging: Finally, after the components are placed on the tape, the system seals the tape to secure the parts and protect them during transport and storage.

Uses of Tray to Tape Packaging

Electronic Components: Tray to tape packaging is perfect for electronic components like ICs, resistors, capacitors, and other sensitive parts. It ensures these parts remain protected during storage and transportation.

Semiconductors: Similarly, tray to tape packaging for semiconductors guarantees that these delicate parts are handled with care and precision.

Precision Parts: For small, delicate parts, tray to tape guarantees proper placement and alignment, which reduces the risk of damage during the process.

Bulk Packaging: Additionally, tray to tape packaging for bulk components is ideal for large batches, allowing for fast and efficient packaging.

Why Choose Tray to Tape Packaging Equipment?

Boost Production Efficiency: Tray to tape systems work quickly and accurately, speeding up the packaging process while handling large volumes with ease.

Lower Labor Costs: Automation reduces the need for manual handling, cutting down on labor expenses and allowing your team to focus on other tasks.

Ensure Product Quality: By using advanced systems like visual inspection and precise component placement, tray to tape machines help maintain high quality and consistency in your packaged products..

equipments we provide

Related Products

Tube-to-Tray Machine

Automates the transfer of tube-packaged components into trays for secure and organized packaging, ready for the next production step.

Vibration Tape and Reel Machine

Uses vibration to feed components automatically into the taping machine, ensuring efficient and continuous packaging for small parts.

Peel Force Tester

A tensile tester is designed to measure the strength, elasticity, and durability of materials by applying a controlled force until the material breaks or deforms!