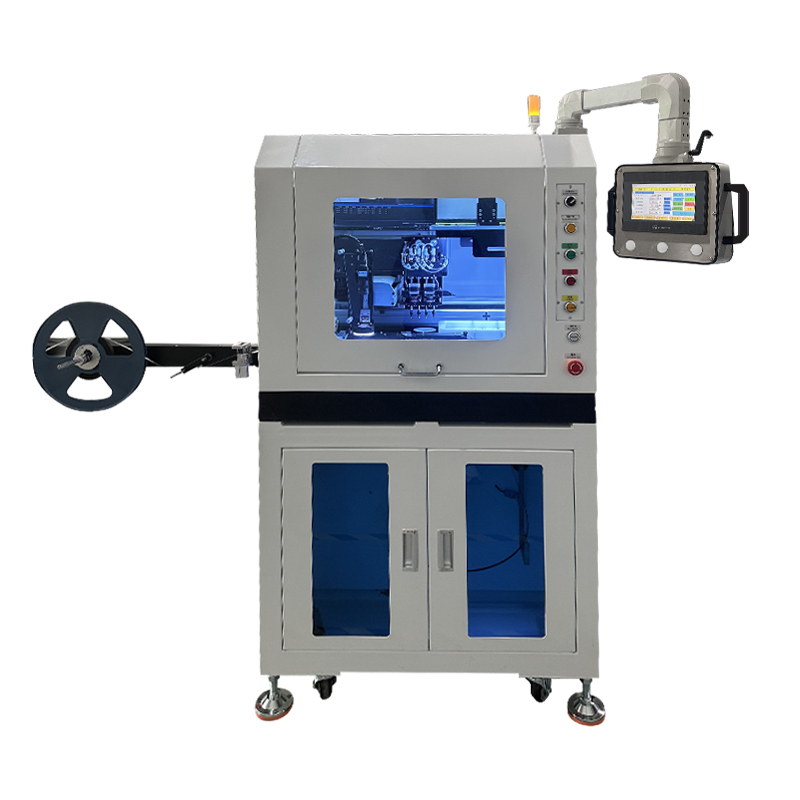

KST-FB20

Automated Flexible Tape and Reel Machine

The KST-FB20 features a flexible feeding system with pick-and-place, testing, inspection, and tape-reeling functions, making it perfect for low-volume, mixed production environments. The multiple input options minimize the need for extra machines, The output can be in either reels or trays, depending on the customer’s needs. The touchscreen interface simplifies setup and reduces operator intervention, ensuring smooth and efficient operation.

Parameters

Feeder: Flexible bowl

Capacity: UPH 3-4K ( device dependent)

Control method: PLC + touchscreen + servo motor

Dimensions: L2204* W960*H1957mm

Power required: single phase AC220V/50HZ

Air supply: 0.4-0.9Mpa

Features& benefits

Flexible bulk input and automated handler with different components

Optional tape output in trays or tapes

User-Friendly Touchscreen interface

Vision inspection available

Reject sorting

Self-adhesive / heat- sealing

Optional and Related Supplies

Get in touch with our sales and technical team to customize a machine to suit your needs today!

<<look into more equipments>>

Automatic Flexible Tape and Reel Machine

What’s a Flexible Tape and Reel Machine?

The flexible tape and reel machine uses a flexible vibration bowl to feed and arrange small parts onto tape. It’s a great solution for packaging parts such as electronic components, sensors, connectors, metal parts, and plastic parts. The flexible feeder can handle different types of products, ensuring no damage to their surfaces. Unlike standard machines, which are built for specific components, this flexible system can package a variety of parts.

How Does a Flexible Tape and Reel Machine Work?

Feeding and Alignment: The parts are placed into the flexible vibration bowl, where they are aligned and positioned using CCD camera inspection technology. The camera checks the parts to make sure they are oriented correctly.

Pick and Place: A robotic arm with a vacuum nozzle picks up the properly aligned parts and either moves them to the next station for inspection or places them directly onto the carrier tape.

Inspection: if the parts are placed on the tape, they are checked for quality. Defective parts are removed, and good parts continue through the process.

Taping and Winding: The machine secures the parts onto the tape and winds them onto reels, ready for shipping, storage, or further processing.

Features of Our Flexible Tape and Reel Machine

Versatile and Compatible: The flexible vibration bowl allows the machine to handle many different types of parts without damaging them. It’s especially good for parts that need careful handling.

Customizable Settings: The machine can be adjusted to suit your specific needs, such as tape tension, speed, and component placement.

Quality Control: The CCD camera inspection system ensures only good parts are packaged by checking the quality before taping.

Why Choose Us as Your Supplier?

Improved Efficiency and cost-effective: Automating the process reduces the need for manual labor and speeds up production, which saves time and cuts costs.

Custom Solutions: We can adjust the machine to meet your specific production needs, whether it’s changing the speed, tape tension, or the feeding system.

Support and Training: We provide training to help your team use the machine effectively. Plus, our customer support team is always ready to assist you if you need help.

FAQs

Our flexible tape and reel machine uses a flexible vibration bowl, so it can handle many types of components without damaging them. Traditional machines are usually designed for specific parts.

Yes, our machine can package a variety of parts, including metal, plastic, and electronic components.

Yes, we offer full training and excellent customer support to help your team operate the machine smoothly.

Contact Us

Want to improve your packaging process with our flexible tape and reel machine? Contact us today to learn more and get a customized solution for your business. We’re here to help you increase efficiency and reduce costs in your production line!

Related Equipments

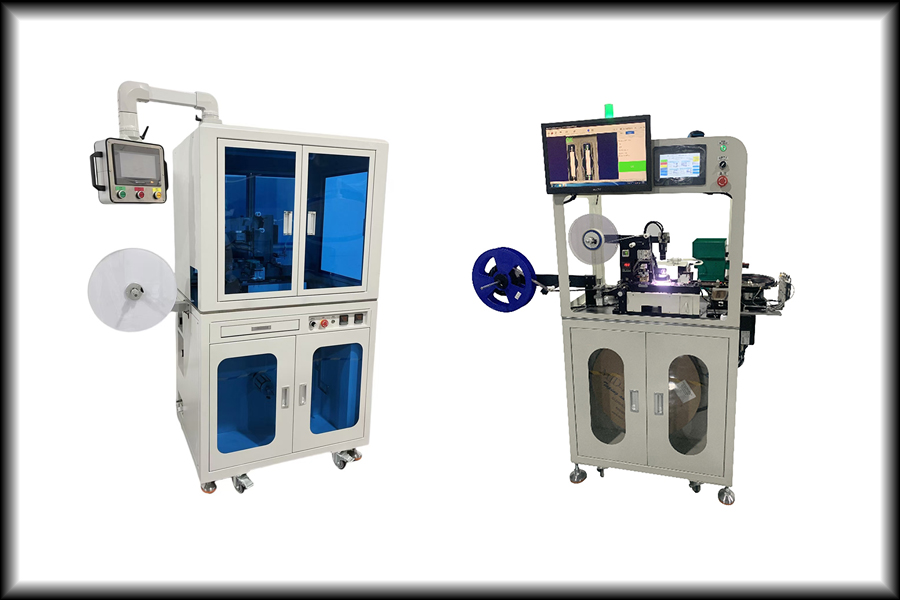

Vibration Bowl Tape and Reel Machine

This machine automatically feeds and arranges small parts using a vibrating bowl, making it great for fast and precise packaging.

Automatic Tube to Tape Machine

This machine moves products from tubes onto tape quickly and carefully, ideal for small parts that need precise handling.

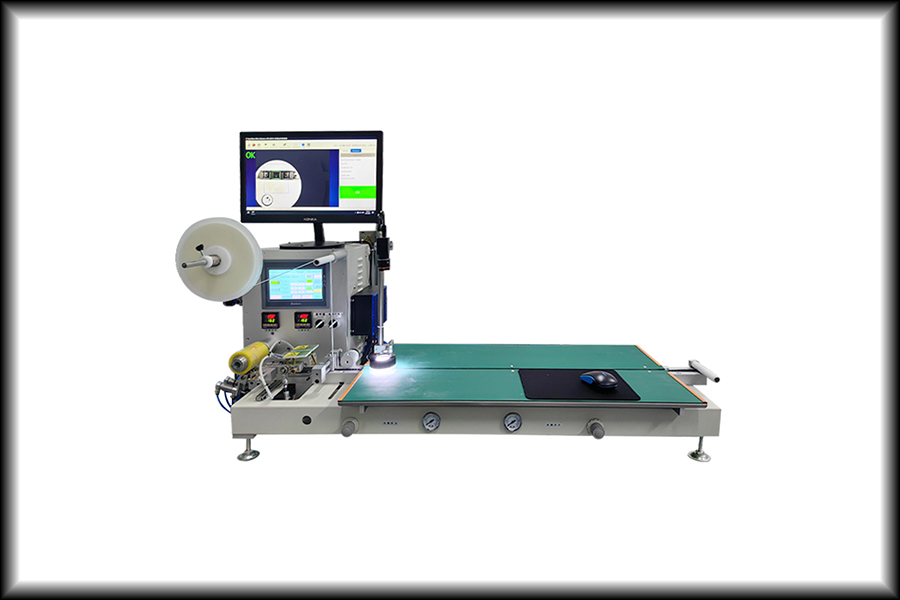

Manual Tape and Reel Machine

A simple, semi-automatic-operated machine that lets workers place parts onto tape, perfect for small batches or special packaging.